Laboratory 4: “Remote” Control Car

Laboratory Description

In this lab, the car is programmed to drive in response to control inputs via a “remote” control with two potentiometers, one each controlling speed and direction.

Laboratory Goals

This laboratory is designed to further a student’s understanding of:

Using an analog to digital converter to measure inputs,

Implementing and tuning an I control routine.

Preparation

Students should complete Activities 12 and 13 prior to starting the laboratory.

Hardware and Tools

RPI-RSLK Robotic Car

2x 10 kΩ potentiometers

[optional] 1x photoresistor (photocell) and 1x 2-3 kΩ resistor

Project Template

Lab4_Template.zip* Read comments thoroughly!!!Or use Lab 3 code with speed control removed (encoder calculations left intact).

Description

This lab entails programming the car to act like a “remote controlled” car, though the remote in this case will simply be a wired protoboard. Below is a figure describing this configuration (in the style of xkcd).

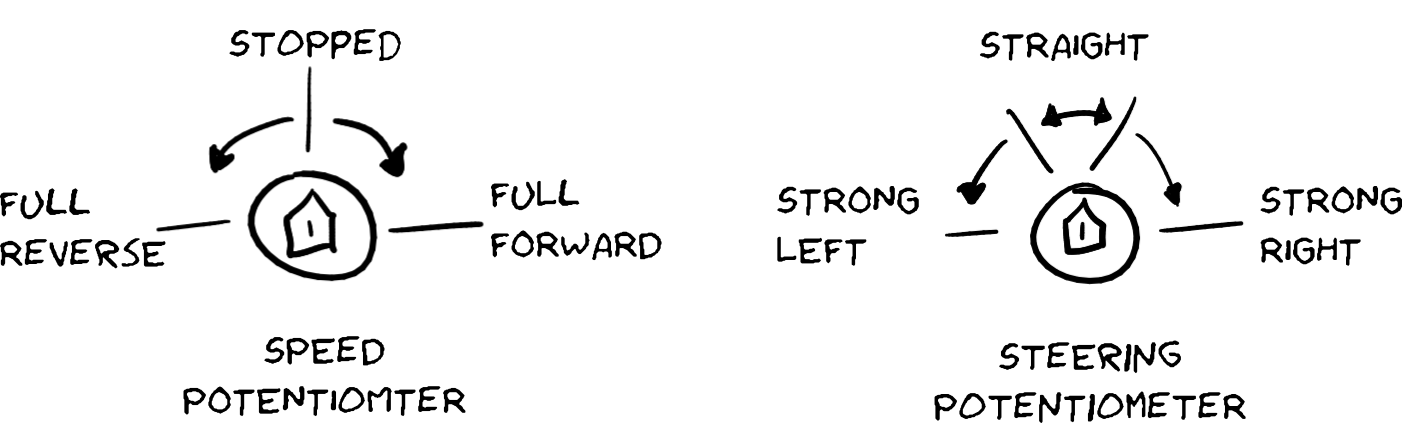

Th remote, which is directly wired to the RSLK using long (e.g., 1 m long) wires, is built such that there are two potentiometers, one which controls the speed of the car and the other controls the turning direction. The potentiometers provided in the lab are easy to turn with fingers only and rotate only over 180°, making them a decent part to use as a control knob. Do not use the potentiometers from the ADALP2000 parts kit for this! Both of the potentiometers should be set such that the midpoint of their rotation is facing away from the user. The functionality of the potentiometers is described in the figure below.

As shown, the speed control potentiometer will will cause the car to be stopped when the wiper is at the midpoint and rotating it clockwise will increase the speed of the car in the forward direction. Similarly, rotating it counter clockwise will cause it to increase in speed in the reverse direction (backwards). Centering the turning (steering) potentiometer will cause the car to drive straight. Driving straight is enforced within a range around the steering potentiometer and not just when it is perfectly centered. Outside of this zone, turning clockwise will cause the car to turn right (or left if driving in reverse). Likewise, turning the potentiometer counter clockwise will cause the car to turn left (or right if driving in reverse).

As the speed of each wheel is adjustable, the wheel speed control must be capable of quickly acclimating to new values. The speed control as used in Lab 3 was effective in producing consistent speed between both the left and right wheels; however, the method used would be very slow to adjust with changing desired speeds. This laboratory presents the use of Integral (I) control to realize a more effective control scheme towards driving the car at non-constant rates.

The car must also be able to turn in a curvilinear fashion via the steering control potentiometer, as opposed to turning in one spot as in Laboratory 3: Predetermined Paths. One method to produce a smooth turn is to control the wheels in a differential fashion. The full control scheme for the lab is presented in the following sections.

ADC and Potentiometers

Potentiometers are variable resistors (simplified) that may be used as variable voltage dividers:

Resistor (left) and potentiometer (right) voltage dividers

A potentiometer has a total resistance, \(R_{pot}\) which is split into “legs”; e.g., \(R_1\) and \(R_2\), such that \(R_{POT} = R_1 + R_2\). The legs are split by the potentiometer’s “wiper”, which is basically a sliding contact along the \(R_{POT}\) resistor, commonly shown in schematic symbols as an arrow. As the wiper is moved up and down on \(R_POT\) (the potentiometer being rotated), the values of \(R_1\) and \(R_2\) will change, resulting in a changing output, where \(V_{out}\) is the voltage on the wiper:

Given this functionality, potentiometers are used very often as control knobs. For this lab, the 3.3 V source should be used as Vin and Vout is attached to a GPIO pin configured as an analog input.

As this lab requires the use of two potentiometers, the MSPM0G3507 may be configured to sample each via both ADCs or have one ADC sample both inputs. Both configurations were demonstrated in Activity 12.

Wheel Speed Control

The wheel speed control specified here replaces the incremental control used in Lab 3 to cause the car to drive straight at a constant speed. This version is a hybrid control system; where:

an open loop portion is used to provide immediate speed modification when a change of speed is requested via the potentiometer. This portion may be viewed as an open loop proportional (unity) gain control, and

an Integral control portion is implemented to compensate for wheel speed errors between the desired speed and the actual speed; useful in reducing the speed difference between the left and right motors.

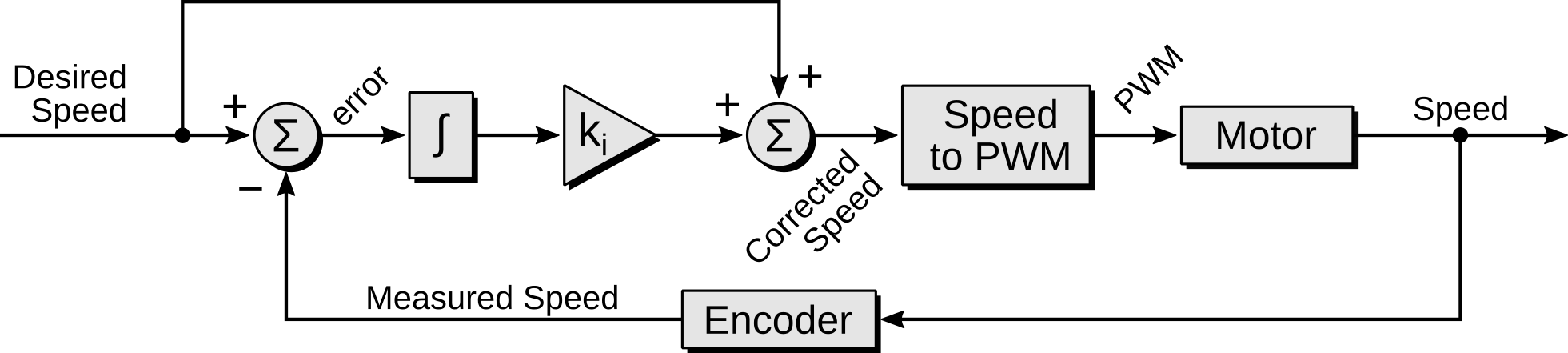

The control system is described in the figure below.

Wheel speed control system

Mathematically, the control scheme presented in the above diagram may be written as:

where \(v_d\) is the desired speed, \(v_m\) is the measured speed, \(v_c\) is the corrected speed, and \(k_I\) is the integral gain constant. The two portions of this control system are the two terms in this equation: the open loop speed, \(v_d\), and the integral component, \(k_I \int \left(v_d - v_m\right)\, \mathrm{d}t\). The error, as noted in the block diagram, is simply the difference between the measured and desired speeds: \(\epsilon = v_d - v_m\).

The control equation provided above is in continuous form. It is necessary to use a discrete form in the program:

This version assumes that the control equation is evaluated on a constant time interval; otherwise, a \(\Delta t(k)\) term must appear in the summation. It is necessary for the control equation to operate on a time scale that is meaningful to the integral control; that is, the car should be able to respond to the previous input before acting on a new error value. This implies that the control equation should be run at approximately the motor response rise time or greater. Values for this range from 50 ms to 300 ms (roughly). For this lab, it is suggested to evaluate the control equation every 100 ms.

This control equation may be used to operate on many measures of the speed; for example: the wheel rotation speed (rpm), the linear speed (m/s), etc. In this instance, we make the assumption that the PWM and its associated duty cycle are valid “measures” of speed; that is, the actual wheel speed will be proportional to the duty cycle. This allows us to formulate the speed in terms of the duty cycle:

Duty Cycle |

Speed |

|---|---|

-100 % |

Full Speed Reverse |

0 % |

Stopped |

100 % |

Full Speed Forward |

With \(v_d\) and \(v_c\) in duty cycle units, the PWM Compare Value to apply to the wheel may be easily calculated knowing the PWM .period.

The above requires that the output of the Encoder be converted into duty cycle units to produce \(v_m\) in order to complete the feedback path. This conversion is provided empirically: the figure below shows a characterization of the encoder response versus a PWM duty cycle along with a rough trendline match of the data (red) [1].

Encoder conversion to speed (duty cycle).

The equation for this above trendline is:

where again, the “measured speed,” \(v_m\), is equal to the “measured duty cycle,” \(DC_m\), and \(N_{enc}\) is the encoder counts.

Pseudocode for the implementation of this control system is provided in the Implementation Guidance section.

Turn Control

The car turn control for this lab assumes that there is a desired speed that the car must maintain while also turning. This implies that the wheels must have different speeds to cause a rotation while also averaging to the desired speed:

where \(v_d\) is the desired car speed, \(v_l\) is the desired left wheel speed, \(v_r\) is the desired right wheel speed, and \(\Delta v\) is the differential speed used to turn the car. The definition of speeds above implies that a positive \(\Delta v\) would result in a left turn.

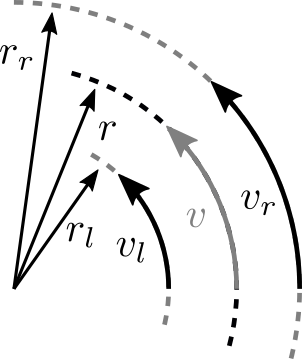

If it is assumed that the wheels do not slip, then the wheels must travel in concentric arcs during the turn:

Turn radius due to differential wheel speed

This implies that the wheels and car center will be travelling at the same angular turn speed, \(\omega_t\), around some center point. Knowing that an arc length may be calculated as

then taking the time derivative of the equation results in the relationship

Again, since \(\omega_t\) is shared between the wheels and center of the car, then

Since the distance between the wheels, \(d_w\), is known or can be measured, \(r_l\) and \(r_r\) can be defined as:

Using the above equations, \(v_l\) and \(v_r\) can be solved for:

This implies that the differential speed, \(\Delta v\) may be calculated as

As clear from this equation, \(v_d = 0\) would result in \(\Delta v = 0\), not allowing the car to turn, or the turn radius must be also set to \(0\) (turning without moving forward or backwards). For the purposes of this lab, it is desired to always allow the car to turn. As such, the calculated \(\Delta v\) from the steering potentiometer must be made independent of \(v_d\). To do this, consider the car driving at some maximum speed, \(v_{d,max}\) and a minimum turn radius, \(r_{min}\). Using these, a maximum differential velocity, \(\Delta v_{max}\), may be found:

The value calculated above is then always the used for the maximum value of the differential speed regardless of the set desired speed; where the differential speed calculation uses this value and the steering potentiometer to generate a linearly increasing desired differential speed as the steering potentiometer is turned further off center.

Implementation Guidance

While the theoretical implementation of the wheel speed control and the turn control is fairly straight forward to build, several problems arise in the actual implementation, mostly attributed to the functionality of the encoders.

Issue 1: The encoder measurements have a significant amount of variation over a 6 sample cycle. It is strongly advised to average the encoder output over 6 cycles (same as Lab 3).

Issue 2: The encoder measurements are not continuous. This is generally not a significant issue when the car is moving; however, when the car is stopped or moving slowly, the control may use outdated values for the encoder. This will have adverse effects on the integral portion of the speed control. This problem may be reduced by disabling the integral control at very low speeds.

Issue 3: The RSLK will not move with low duty cycles. Therefore, it is useful to force the desired speed to 0 if it desired speed is below a minimum threshold.

Considering the control schemes presented and the issues and solutions provided above, the following pseudocode is the suggested method for implementing this laboratory.

Global variables/prototypes/etc.

main:

Initializations

Enforce a startup delay of 1 second (delay_cycles(32e6))

Turn on the motors

Infinite while loop:

If 100 ms has passed:

Trigger the ADC(s) to read both potentiometers

Convert the speed potentiometer measurement to a desired speed

Ensure the desired speed follows the control specifications below

Convert the steering potentiometer measurement to a differential speed

following the specifications below.

<-- Start Left Wheel Speed Control -->

calculate desired wheel speed as desired speed +/- differential speed

if |desired wheel speed| is less than minimum value,

set the desired wheel speed and compare value to 0

otherwise:

set wheel direction depending on sign (+/-) of desired wheel speed

calculate the current speed error from the encoder and |desired wheel speed|

(use trendline equation from figure for current speed)

add current speed error to an "error sum" variable (tracking integral error)

calculate the corrected speed using the discrete equation above (should be >= 0)

convert the corrected speed (duty cycle) into a compare value

enforce minimum and maximum limits on the compare value

apply the compare value

<-- End Left Wheel Speed Control -->

<-- Repeat Above for Right Wheel -->

Other Functions:

GPIO Init (usual stuff)

Timer Init:

PWM Timer+CCRs (32 kHz, UP Mode, ZERO_SET|UPCOMPARE_CLEAR <- makes control easier)

Encoder Timer+CCRs

100 ms Timer

ADC Init:

Fill in as needed

Encoder ISR:

Generally the same as in Lab 3 except no incremental PWM control.

Still perform 6 sample averaging for both encoders but save averages

to global variables (for use in control above)

100 ms Timer ISR:

Mark that 100 ms has passed using a global flag

Control Specifications

Quantity |

Value |

Notes |

|---|---|---|

Min |Speed|, \(v_{d,min}\) |

10 % |

Set |desired speed| to 0 if less than |

Max |Speed|, \(v_{d,max}\) |

50 % |

Set |desired speed| to this if greater than |

Min PWM DC % |

10 % |

Set compare value to this if less than |

Max PWM DC % |

90 % |

Set compare value to this if greater than |

Minimum turn radius, \(r_{min}\), at \(v_{d,max}\) |

0.2 m |

Use to calculate maximum differential speed |

- Notes:

The min/max |Speed| limitation is not the same as the min/max PWM limitation: the restrictions on |Speed| affect the desired speed (before the control algorithm is evaluated) whereas the restrictions on the PWM affect the signal applied to the motor (after the control algorithm is evaluated). If the car is turning at max speed, it must be that the individual wheel speed of a one wheel is higher than the specified max |Speed|, otherwise the car will not turn correctly; therefore, this max |Speed| is applicable only to the desired speed before the addition/subtraction of the differential speed.

The minimum turn radius is used to calculate the maximum differential speed between the wheels when the car is driving at the specified max |Speed|. Use this value to calculate the differential speed from the steering potentiometer. Note that this value will not change, regardless of the actual desired speed.

Part A

Wire the potentiometers on your protoboard and connect to two ADC channels; selected from ADC Channel Pin Map. Cut or reuse long lengths of wire (several feet) to connect the potentiometers to the car. Note that you only need 4 total wires to accomplish this.

Implement the wheel speed control with speed potentiometer input for one wheel only. The other wheel during testing should not be enabled or moving. You will need to generate a conversion equation that maps the ADC output to a desired speed, following the requirements in the control specifications table above. It is suggested to use float type variables for all pieces of the speed calculation to allow more accurate and non-integer values of duty cycle.

Hint

The “conversion equation” noted above for determining the desired speed could be in the form \(y = m x+b\).

A first step in verifying the control operation will be to specify \(k_I = 0\) to test the open loop control portion. This should result in the car spinning the wheel at roughly the right speed but likely have some error. Print out the desired speed, \(v_d\), and encoder measured speed, \(v_m\), (both in PWM Duty Cycle “units” as described) to verify.

Once this is shown to work, \(k_I\) should be set as a non-zero small number, and increased until acceptable operation is achieved:

A too low value of \(k_I\) will resemble the response with \(k_I = 0\).

A too high value of \(k_I\) will result in the wheel misbehaving (e.g., jerking between fast/slow, not settling on correct speed)

A good value for \(k_I\) will result in the wheel setting to the desired speed quickly.

A suggested start value for \(k_I\) is 0.001 (float!), increasing by a factor of 10 for each test and then fine-tuning when the correct magnitude is found.

When testing your control scheme, it is useful to print out many quantities each cycle:

Initial Desired Speed

Modified Desired Speed (after applying minimum/maximum thresholds)

The encoder “measured speed,” \(v_m\), (duty cycle “units”)

speed error summation (integral error)

Corrected Speed, \(v_c\), (duty cycle “units”)

PWM compare value

If, when operating at a constant speed, the speed error summation does not stabilize (e.g., continuously increases or jumps by very large amounts up and down), it is possible that \(k_I\) should be negative for your implementation. Also, make sure that the variables used for each portion of the control make sense and you aren’t getting (1) integer overflow or (2) integer division to 0.

While it is feasible to use your completed lab 3 code as a starting point for lab 4, it is strongly suggested to use the provided template project: Lab4_Template.zip. If you prefer to use your lab 3 code, ensure that ensure that the previous version of speed control is removed from the Encoder ISR while keeping the 6 element averaging, with the final average stored as a global variable.

Checkoff

Demonstrate that the speed control potentiometer successfully controls a single wheel of the RSLK (other wheel is OFF) from -50% duty cycle speed to 50% duty cycle speed. The wheel should stop when the potentiometer is centered. A terminal printout of the Desired Speed, \(v_d\), the encoder measured speed, \(v_m\), and corrected speed, \(v_c\) must be provided showing convergence of \(v_d\) and \(v_m\).

Part B

Copy the wheel speed control to the other wheel and enable it. Again verify that it works properly by disabing the already verified wheel and testing. Once complete, enable both wheels and ensure the car drives straight with changing desired speeds. Slight turns are acceptable when large speed changes are requested but the car should straighten quickly.

Add turning control to the car once the car can drive straight. The car should not turn if the steering potentiometer is within ±15° of center and then should linearly increase turn strength (differential speed) with increasing potentiometer angle. The maximum turn radius will change with varying desired speeds; however, the maximum turn strength (again, differential speed) should be consistent across all desired speeds. With this configuration, the car should be capable of spinning in place when the speed potentiometer is set to cause the RSLK to stop.

Checkoff

Demonstrate the additional components as described above. Submit your final code to the Gradescope assignment.

Do not discard your long wires! They may be used in Lab 5.